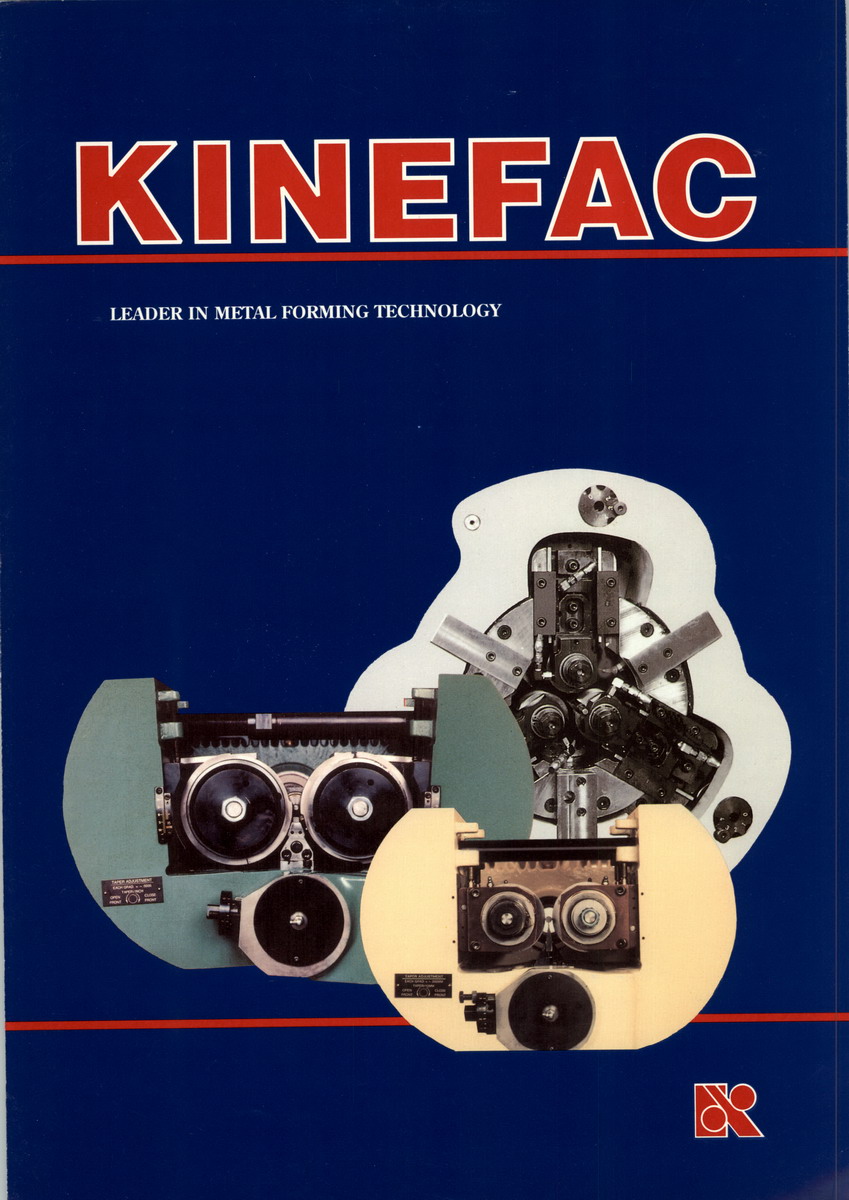

Kinefac® was founded in 1962 to develop cylindrical die thread rolling machines. In the years since, it hasbecome a world class developer and manufacturer of specialized metal forming, metalworking andprocessing equipment. Today the Kinefac Division products are sold worldwide. Initially, its patented Kine-Roller® thread rolling machines and Kine-Form® dies were used to produce fasteners for the U.S.market. As the automotive industry moved toward cold formed and near net shaped shafts for steering,starters, alternators, wipers, power windows and seat adjusters it applied its rolling capabilities to this market. To provide blanks for these shafts it developed its patented Kine-Turn® center drive lathes. As use of hollow shafts grew they introduced the advanced Kine-Xtrude® CNC metal extrusion machines.As its cold forming laboratory capabilities grew, it formed the Kine-Pro Division to perform unusual or difficult rolling, coiling and extrusion operations for customers who desired an outside source for such parts. Having built up internal capability to engineer hydraulic power units and pneumatic part handling systems, it established the KinePower Division to exploit it in New England. Subsequently, the

Sleeper and Hartley spring making machine business was acquired and has since evolved into the Kine-Coil/Sleeper Division. Today they produce leading edge Micro-Coilers for the production of very small medical coils and other specialized spring making equipment. Most recently, Kinefac acquired the Barrett Centrifugals product line and is now applying this technology to a variety of new applications of centrifugal fluid reclamation, chip cleaning and parts washing and drying. Throughout its 50 year history, the success of Kinefac® has been built on a cohesive team of engineers, designers, assemblers and its supporting staff committed to establishing worldwide leadership in its various niche markets.